PI: Michael P. Short, Department of Nuclear Science and Engineering, MIT

Abstract

Nuclear reactors represent the harshest, most extreme environment man can make. Corrosion resistance, often exacerbated by radiation, is of paramount importance to the safe and reliable operation of nuclear reactors. To date corrosion has been the Achiles heel of the liquid-lead cooled reactor, as no single material can provide the required strength and corrosion resistance at a reasonable cost. Plused plasma steel coatings, which have shown superior corrosion resistance using a cheap, industrially scalable surface treatment, could fill this gap. However, no method exists to fully replicate their performance in a nuclear reactor. We will use a unique corrosion/irradiation facility to replicate the environment and conditions in a liquid lead-cooled nuclear reactor, to study if and how these coatings resist corrosion in a high radiation environment. Success will lead to safer nuclear reactors, more efficient concentrated solar power plants, and testing a controversial hypothesis that radiation sometimes slows down corrosion.

Report

- Project Title: In Situ Corrosion/Irradiation of Steel Coatings for Liquid Lead Nuclear Ractors

- Principal Investigator: Michael Short (MIT), Pavel Dzhumaev (MEPhI)

- Grant Period: March 2018 – February 2019

Summary

The project team has finished construction and long-term testing of the radiation/corrosion beamline using molten salts, and through rigorous testing has confirmed the mechanism of radiation-decelerated corrosion. This is now sure to apply in liquid lead, the primary purpose of this project. Specimen and beamline drawings were delivered to MEPhI for sample construction. Unfortunately the sample fabrication equipment encountered serious technical issues, thus Prof. Dzhumaev’s visit was not possible during the time of this grant. We still plan to host him at MIT once his samples are complete, as our beamline is ready to conduct his experiments.

Background

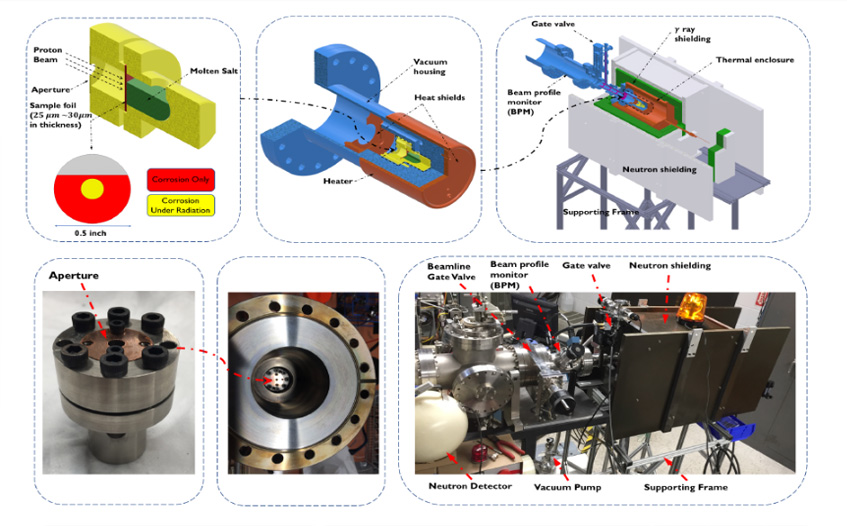

While building and testing our beamline for radiation-affected corrosion (see Figure 1), it was discovered that the application of proton irradiation actually decelerated corrosion in molten salts[1]. The effect was hypothesized to be due to radiation damage generating point defects, and radiation induced segregation (RIS) or the Inverse Kirkendall effect causing chromium segregation away from grain boundaries (GBs). This would lead to less Cr on GBs, slowing salt corrosion via Cr dissolution.

Figure 1: Irradiation/corrosion beamline used in this project

This mechanism should follow a generalized principle: Any time the corrosion mechanism is selective dissolution of the larger solute element, then radiation damage should slow corrosion. There exist two practical situations where this effect should be present – in molten salts (previously tested), and in molten metals, particularly lead and lead-bismuth. Meanwhile. Prof. Dzhumaev of MEPhI has been developing pulsed plasma coatings of steels to slow corrosion in lead and lead-bismuth, which would represent a promising technology to derisk lead-cooled reactors. Herein lies the potential benefit to SkolTech and Russia – as Russia is the only country on Earth commercializing lead-cooled reactors, such as the BREST-300 and the SVBR-100. Should radiation decelerate corrosion in these systems, it will represent a major derisking effort for their commercialization.

Technical Progress

Our project consisted of three main parts: (1) Beamline testing and mechanism confirmation, (2) Delivery of beamline chamber and specimen drawings to MEPhI with experimental coordination, and (3) Visit by Prof. Dzhumaev to MIT to conduct experiments. The first two parts were completed, while the third has not yet been done due to factors outside of our control.

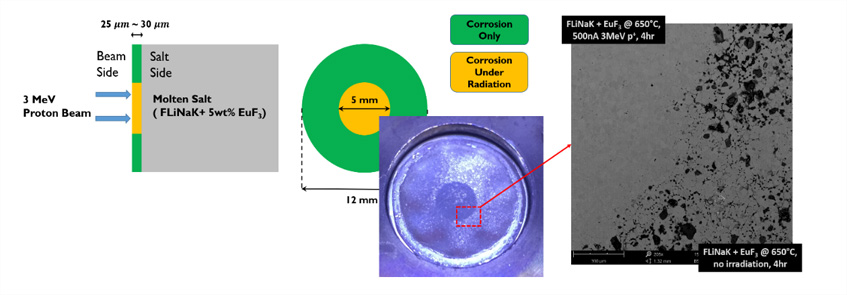

Much of the funds in this project were used to pay the RA and complete fabrication and testing of the radiation-decelerated corrosion beamline. The results exceeded our wildest expectations – In every test we ran below 700℃, the application of proton radiation slowed corrosion by a factor of 2-3x, as shown in Figure 2. Here a schematic of the specimen is shown at left, demonstrating how the yellow region in the center is exposed simultaneously to proton irradiation from the left and salt corrosion from the right. Meanwhile the green region sees only salt corrosion, allowing an apples-to-apples comparison with and without irradiation. The results are so striking that they can be seen with the naked eye (center), and in the electron microscope one can see the curvature of the proton beam in “cleanliness space.”

Figure 2: Schematic and typical results of radiation-decelerated corrosion in Ni-20Cr exposed to 650℃ FLiNaK salt for 4hr

Varying the proton beam conditions allowed us to refute competing hypotheses, that the proton irradiation may be making the salt in the center less corrosive. Figure 3 shows results to the contrary, as any series from left to right (increasing proton beam current) shows an increase in corrosion rate, while comparing any series from top to bottom (with or without radiation) shows that proton radiation slows corrosion in all cases. The results in Figure 3 show just three of the over twenty tests we ran to confirm this effect, while varying the exposure time, EuF3 salt buffer concentration, temperature, and proton beam current. These tests allowed us to empirically show that our proposed mechanism is indeed the dominant one, lending strength to the idea that this effect will persist in lead-cooled reactors. In addition, when moving from this proton-based experiment to a neutron-based reactor the slowdown in corrosion will be even more pronounced, as the neutrons will not make the salt more corrosive as exhibited in our experiments.

Mechanistic proof of the proposed mechanism followed thanks to Dr. Yang Yang of Lawrence Berkeley National Lab, who performed focused ion beam (FIB) extraction of selected grain boundaries and conducted transmission electron microscope (TEM) elemental linescan analyses. His results summarized in Figure 4 showed an enrichment of Ni with a depletion of Cr in the irradiated grain boundaries, while those outside the irradiation area showed depletion in both Ni and Cr. Thus our proposed mechanism has been confirmed in this project, competing hypotheses refuted, and strength given to the argument that this effect will persist in lead-cooled reactors.

Cooperation with MEPhI

Some of the funds were used by Prof. Short to make two trips to Russia, one specifically to coordinate experiments and timing with Prof. Dzhumaev, the other in combination with a conference in the Ural mountains on radiation damage in metals and alloys. Weiyue Zhou, the RA on the project, created a set of CAD drawings and line drawings for Prof. Dzhumaev to construct new chambers out of pure Mo, which is the only required modification to the beamline to adapt to liquid lead (our current setup uses pure Ni, impervious to corrosion in molten salt). Molybdenum was chosen for its extremely low solubility in molten lead, thus making it the most cost-effective and impervious material there is.

Next, Prof. Dzhumaev needed to procure a pulsed plasma surface coater from Tomsk University, which he had previously used to fabricate coatings in the past. He was due to visit MIT over the summer of 2018. Unfortunately the overly bureaucratic system of approvals in MEPhI, coupled with the deteriorating relations between the US and Russia (so I was told indirectly), meant he failed to obtain high-level approval for this visit in the summer. We then planned for him to visit over IAP 2019, for which he was able to obtain approval, but by then the plasma coating equipment in Tomsk had broken and required repairs. We then planned for a February/March 2019 visit, but still the equipment was broken and samples could not be made. Molybdenum chambers have been made, and once the equipment from Tomsk is repaired we still intend to host Prof. Dzhumaev’s visit to conduct this work – just because the project is officially over doesn’t mean we won’t still give this experiment a shot. To fund this visit we obtained written permission from the SkolTech administrators to use the funds for a second trip for Prof. Short to travel to Rusisa for the Urals conference and to coordinate with Prof. Dzhumaev, while he has set aside an equivalent sum in discretionary funds to host Prof. Dzhumaev when he is available. Thus funding exists outside the project structure to finish this project. A no-cost extension was not allowed, as the end date of the project coincided with the final end date of the entire MIT-SkolTech collaboration.

[1] Zhou, W., Woller, K. B., Zheng, G., Stahle, P., Short, M. P. "A Simultaneous Corrosion/Irradiation Facility for Testing Molten Salt-Facing Materials." NIMB 440:54-59 (2019). Link to paper